FDA-Approved Bioprinted Nerve Repair: COAPTIUM CONNECT and the Future of Regenerative Medicine

- Adreeka jeet

- Jul 22, 2025

- 4 min read

In a major advancement for regenerative medicine and 3D bioprinting, 3D Systems, with the assistance of the French medtech company TISSIUM, received FDA De Novo clearance for COAPTIUM CONNECT a fully bioabsorbable, suture-less 3D-printed implant used for peripheral nerve repair. This event is a pivotal moment in medical history, as the FDA-cleared bioprinted implant is the first ever FDA-cleared bioprinted product designed specifically to promote healing in injured nerves. It also signifies a paradigm shift toward less invasive, personalized, and biointegrated surgical solutions.

Peripheral nerve injuries are often caused by trauma, surgical complications, and repetitive strain injuries, and can negatively impact one's quality of life. Peripheral nerves are responsible for sensory and motor function throughout the body, and when damaged, patients can experience numbness, pain, muscle weakness, or even permanent loss of mobility. While traditional and widely available methods for repairing peripheral nerves include suturing and nerve grafting, these repairs are limited to particular surgical expertise, prolonged recovery, and typically very invasive microsurgery. There are also instances in which suturing misaligns the nerves and/or additional scarring inhibits repair, while COAPTIUM CONNECT uses innovative technology to truly change the game as a tool.

The COAPTIUM CONNECT device is specifically designed to connect mixed peripheral nerves without the use of sutures. It is constructed from a light-cure photopolymer, which is biocompatible, customizable, and completely bioabsorbable, meaning that once the nerve is repaired, the device completely breaks down and dissolves in the body. Utilizing 3D bioprint technology allows each implant to be produced with specific dimensions and a tailored structure, aligning nerve ends perfectly, and resulting in more favorable functional recovery. Ultimately, this new approach eliminates the need for sutures and significantly reduces operating time, streamlining the full nerve repair process and making it more convenient.

Possibly one of the most interesting aspects of this approval is that it was achieved through the FDA's De Novo classification pathway, which is specifically designed for unprecedented medical devices that do not have any equivalent on the market. This pathway is crucial because it allows for the introduction of innovative products that can address unmet medical needs, thereby confirming not only the safety and efficacy of the device in question but also highlighting the significant demand for such a solution. The approval signifies a pivotal moment in the regulatory landscape, as it suggests an increasing acceptance and recognition by regulatory bodies for bioprinted medical products. This trend is particularly noteworthy given the complexities and challenges associated with bioprinting technologies, which involve the intricate layering of living cells and biomaterials to create functional tissues. Moreover, the successful navigation of the De Novo pathway for this bioprinted device sets a precedent that could pave the way for a variety of future innovations in the field of bioprinting. For instance, we might soon see the development and clinical application of bioprinted bone scaffolds that can facilitate the regeneration of bone tissue in patients suffering from traumatic injuries or degenerative diseases.

Similarly, the potential for bioprinted cartilage patches could revolutionize treatments for joint injuries and conditions such as osteoarthritis, offering patients new hope for recovery and improved mobility. Furthermore, the ambition to create fully functional organ tissues through bioprinting could address the critical shortage of organ donors, providing a viable alternative for transplantation. As the field evolves, the implications of this approval extend beyond just the immediate applications of the technology. It signals to researchers, investors, and healthcare providers that bioprinting is not merely a theoretical concept but a practical avenue for advancing medical science. The regulatory endorsement fosters an environment conducive to further research and development, encouraging innovative minds to explore the vast possibilities that bioprinting holds. With continued advancements in materials science, cellular biology, and engineering, the future of bioprinted products in clinical settings looks promising, potentially transforming the landscape of regenerative medicine and personalized healthcare.

The two companies behind this innovation include 3D Systems, a world leader in advanced additive manufacturing, and TISSIUM, a Paris-based biotech start-up that aspires to develop programmable biomaterials. The two companies complement each other: 3D comes from a history of engineering excellence while TISSIUM excels in the biologic space. This audit product merges both worlds to create a product that is clinically functional and biologically compatible. TISSIUM is known for developing performance-based, tissue-integrated solutions and COAPTIUM CONNECT is an offshoot of this ethos applied to nerve repair.

So, what does this mean for surgeons and patients? Surgeons can complete the surgery with less complexity and time; they are no longer required to manually piece together delicate nerve fibers. The result is faster procedures, all while maintaining (or increasing) precision and lowering risks (i.e., risk of misalignment or post-operative inflammation). For patients, decreased complexity equates to decreased healing, decreased complications, and possibly even decreased functional limitations compared to traditional techniques, and fewer follow-up interventions, including follow-up surgical interventions. Lastly, there is no need for the second surgery to retrieve the device because it is fully bioabsorbable!

Even though COAPTIUM CONNECT has very recently received FDA clearance, it is expected to be introduced to the market at large by 2026, permitting time for physician education, manufacturing ramp-up, incorporation into surgical protocols, and also time to conduct more clinical studies to optimize and establish norms about utilizing the implant for the various types and severities of nerve injuries.

This advancement is much more than a clinical development—it is a vision of the future becoming reality. The successful combination of bioprinting and getting regulatory approval for an implant demonstrates that 3D bioprinting is not limited to research labs or prototypes. It becomes a useful tool in actual clinical environments, and new uses for technology will continue to emerge at a rapid rate. Once technologies such as COAPTIUM CONNECT demonstrate value enhancement in patient care, there will be a flood of innovation about printed custom tissue scaffolds, vascular grafts, skin grafts, and possibly organs.

In summary, COAPTIUM CONNECT is much more than a new surgical instrument; it is a representation of how precision medicine, bioprinting, biotechnology, and advancements in the medical field continue to converge to solve real-world problems. COAPTIUM CONNECT the sutureless, dissolvable, and patient-customized implant is not only changing people's lives for the million (up to 50 million in the U.S. alone); it will revolutionize the field of nerve repair and influence faster and smarter treatment pathways for patients requiring nerve repairs.

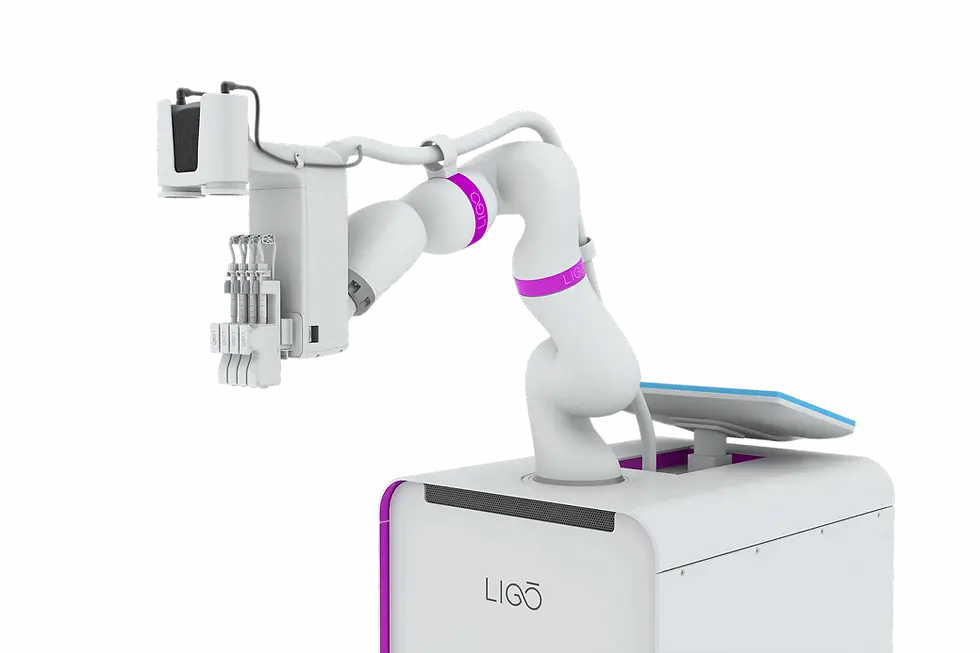

COAPTIUM CONNECT with TISSIUM LIGHT

Comments